In the recently published ‘Utilization of urea as an accessible superplasticizer on the moon for lunar geopolymer mixtures,’ researchers come together from around the world to examine new and unusual materials for construction away from earth; here, they are considering development of geopolymers for fabrication of components on the moon—with as few of them as possible to be carried from Earth.

While many may be surprised that the researchers began investigating the uses of urea, it is not as uncommon a choice as it may seem to the layperson, especially as a chemical admixture capable of breaking hydrogen bonds and reducing viscosity—along with the fact that is available anywhere humans dwell. This is only one of many challenges, however, as colonizing the moon also brings forth issues like how to deal with:

- Meteoroids

- Vacuum

- Radiation

- Extreme temperatures and fluctuations

In taking a trip to the moon, it costs (according to NASA) around $10,000 just to transport one pound of materials into orbit. For obvious reasons, all organizations involved encourage the development and use of materials created in space if possible. Putting lunar surface materials to use in creative ways is a major focus in the study of such journeys and colonization and construction, but ultimately researchers usually find that weighty consumables are still required.

“Since water is a highly valuable resource on the lunar surface and not readily available, using building materials with high water demand is practically impossible,” state the researchers. “Geopolymers consist of silico-aluminates in an amorphous to semi-crystalline three-dimensional structure. Geopolymers exhibit an excellent performance such as quick controllable setting and hardening, high compressive strength, freeze-thaw resistance, excellent durability in sulfate environment, and superior resistance to acid and salt attacks, high fire resistance, and low thermal conductivity, small shrinkage, and adequate radiation shielding.

“Utilization of lunar regolith and alkali metals as the components of geopolymer composites can thereby facilitate lunar construction without the need of bringing materials in from the Earth at extreme cost.”

With the obvious lack of water in space, researchers realize that the best option is the addition of an admixture or superplasticizer—and one that is already available on the moon. If humans are available, then so is human waste:

“Human urine contains about 9.3–23.3 g/L urea,” state the researchers. “It is well known that urea is capable of breaking hydrogen bonds, thereby reducing the viscosities of many aqueous mixtures. It is therefore reasonable to assume that urea might work as a superplasticizer to reduce the water demand of the geopolymers.”

The researchers used a regolith simulant for this study.

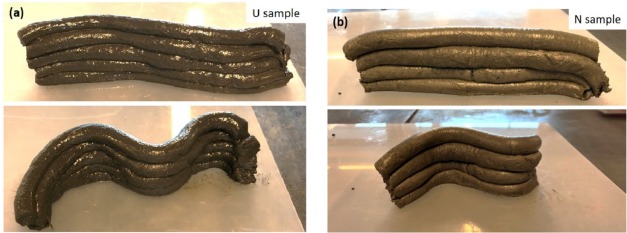

One of the major challenges for the team during this study was to maintain the shape of the samples after extrusion. They found that the sample with urea was able to keep its shape better. Three different types of materials were evaluated, however, with the control mixture without superplasticizer proving to be too stiff for casting, resulting in fractures structures—along with the polycarboxylate superplasticizers too. Urea and naphthalene-based superplasticizers proved to be castable upon molding with smooth surfaces, maintaining their shape. With the addition of 3 percent urea, the researchers were able to postpone setting times. The urea sample also displayed high compressive strength, along with the highest amount of gel formation.

“Overall urea exhibits promising properties as a superplasticizer for 3D printing of lunar geopolymers,” concluded the researchers.

“Further studies are needed in order to assess how these lunar regolith geopolymers will behave under the severe lunar conditions, with a vacuum that can cause the volatile components to evaporate, and large temperature fluctuations which might cause crack formation. The ability of the geopolymers formed under these conditions to withstand meteorite bombardment, and to shield against high radiation levels should also be evaluated.”

3D printing in space has been the topic of much research, along with the subject of materials for constructions—from studying advanced materials and manufacturing to preparing suitable ways to live on Mars. What do you think of this news? Let us know your thoughts! Join the discussion of this and other 3D printing topics at 3DPrintBoard.com.

[Source / Images: ‘Utilization of urea as an accessible superplasticizer on the moon for lunar geopolymer mixtures’]

If you're looking for affordable 3D visualization services in the USA, our platform provides an ideal solution for all your architectural and real estate needs. Through our service, you can access high-quality 3D renderings at competitive prices without compromising on quality. Whether you need interior visualizations, exterior renderings, or architectural animations, our team ensures that you get professional results that fit within your budget. With our support, you can make your projects visually stunning while saving on costs, all with a quick and straightforward process.

Through our site, you can easily order affordable 3D visualizations for your projects, whether for a residential property, commercial development, or architectural design. We understand the importance of staying within budget, and that's why we offer tailored solutions to ensure you get the best value for your investment. Our experts work efficiently to provide you with realistic, photorealistic 3D images that will elevate your presentations and attract clients, making your property stand out in the market.